PRODUCTS

Jiangsu kanazawa heavy machinery co., LTD.,

Service hotline:+86-13901477088

Tel:+86-513-88661999

Fax:+86-513-88661199

Phone:+86-13901477088

E-mail:info@jsjzzj.com

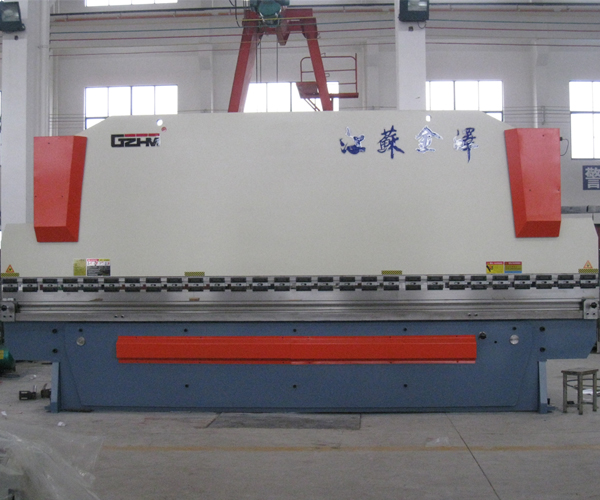

WC67K-250T6000CNC hydraulic sheet metal bending machine

1, the important technical parameters

The serial number

The name says

Number of values

Single bit

For note

1

Nominal pressure

2500

KN

2

The length of the table

6000

mm

3

The distance between the pillars

4500

mm

4

The depth of the throat and mouth

400

mm

5

stroke

250

mm

6

The workbench between the slider and the biggest opening height

540

mm

7

Stroke volume adjustment

160

mm

8

The main motor power

22

KW

2, the machine characteristics

Taken the frame adopts full steel welding structure, have sufficient strength and rigidity, and through the vibration aging treatment after welding, eliminate internal stress, ensure the overall accuracy of the fuselage.

U use large ground boring and milling machine, with a processing method, precision processing, in order to ensure the machining accuracy.

U used in hydraulic transmission.

Taken the slider synchronous mechanism adopts mechanical torsional axis synchronous, the oil cylinder built-in mechanical block to control the slide block end position, accurate location, workpiece Angle good consistency.

After u keep-off device and the upper slider stroke using CNC control.

3, machine noise measurement standard

A sound pressure level meter right LPA < 82 db (A)

A weighting sound power level LWA < 94 db (A)

4, implement standard machine

JB/T2257.1-1992 "sheet metal bending machine technical conditions"

JB/T2257.2-1992 "sheet metal bending machine type and basic parameters"

JB/GQ - F2012-86 "quality classification standard of sheet metal bending machine products

DBS002-91 "sheet metal bending machine performance and test methods"

5, key component list

The serial number

The name of the

specifications

The number of

origin

1

Asynchronous motor

1

nantong

2

The main electrical appliances

1 set of

schneider

3

The gear pump

1

Shanghai/nantong

4

Hydraulic valve

1 set of

JianHu/nantong

5

Oil cylinder

1 set of

JianHu/nantong

6

The seals

1 set of

Japan KVK

7

Numerical control system

1

Italy/the Netherlands

中文版

中文版  ENGLISH

ENGLISH